Moonshot Missions is a partner of the Environmental Finance Center Network (EFCN), offering no-cost solutions to small communities that need technical assistance. Through boots-on-the-ground initiatives, we provide technical, managerial, and financial support to water and wastewater utilities in need.

Spins Process Control Method

In wastewater treatment, effectively managing the activated sludge biological process is critical to maintaining compliance with water quality regulations. The Spins Process Control Method stands out as an important and efficient tool for wastewater operators to employ as part of their daily rounds to effectively manage this process. Developed in the 1980s by Lynn Marshal, this method offers a rapid and reliable way to assess solids mass and their distribution throughout the wastewater treatment process. It’s a technique that offers tremendous operational efficiency and is easy to use and implement for all wastewater treatment plant operators.

Rapid Analysis for Real-Time Decision Making

At the heart of the Spins method is its ability to deliver actionable data within 15 minutes. Utilizing centrifuges, operators can quickly gauge the solids concentrations in sludge samples. This quick analysis, processing six or more samples at a time, turns process control from a guessing game into a precise science.

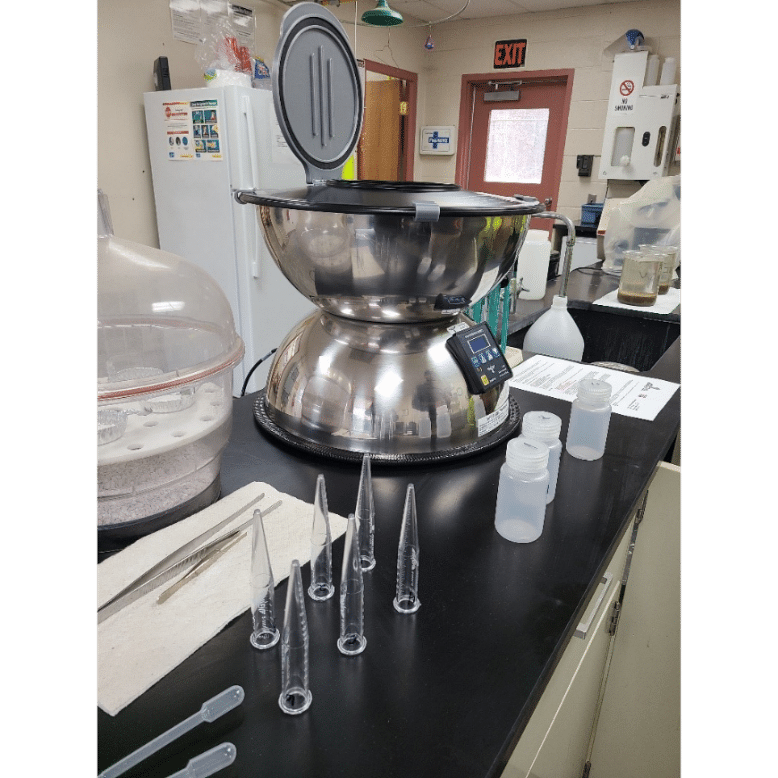

Implementing the Spins method doesn’t require complicated tools or instruments. With an initial investment of approximately $1,700, a treatment facility can be equipped with all the necessary tools: a centrifuge, six test vials, Settleometer and a sludge core sampler.

The Method in Motion

The spins method is focused on tracking the quantity, quality, and location of the solids in the process. It is a tool operators use to monitor the level of solids added and removed in the system to maintain the biological process. This balance is critical for both the separation and nutrient conversion phases of wastewater treatment, which are interdependent and important for achieving compliance.

The Spins method empowers facilities to adapt to the ever-changing environment of the biological process, offering strategies to monitor and adjust the treatment process effectively. Among these strategies is incorporating process control testing for ammonia-N along with the solids testing. The use of simple, non-reportable ammonia test kits can provide a cost-effective tool to test for the presence of ammonia-N in the process.

Empowering Operators

The ultimate goal of the Spins Process Control Method is to enhance facility performance, ensuring operators are in control of the plant and not the other way around. This method equips operators with the knowledge and tools needed to navigate the complexities of wastewater treatment, encouraging a proactive rather than reactive approach.

Summary and Takeaways

The Spins method has been field tested and found to be an effective tool that produces rapid results (see Activated Sludge Manual of Practice, first edition). It is a tool that provides defensible data to help keep any plant in compliance. Consistent data relies on consistent operational methods. If you need help, give us a shout. We are here to help and if you feel like you have hit a wall and are unsure what to do next, don’t hesitate to contact me at any time.

Moonshot Missions is here to help and if you feel like you have hit a wall and are unsure what to do next, don’t hesitate to contact me at any time:

Nathan W. Coey

Senior Utility Advisor

Moonshot Missions

740-817-2121