In this blog, we are talking with Sharon Nall of the New Hampshire Department of Environmental Services (DES) where she oversees the Planning, Protection and Assistance Section within the Wastewater Engineering Bureau. Our discussion focuses on the state’s Wastewater Treatment Facility Energy Efficiency program and how it has reduced costs and carbon emissions at small wastewater treatment plants. In our interview with Sharon, she provides an overview of the program and discusses some of the program’s benefits.

Tell us how New Hampshire’s Wastewater Treatment Facility Energy Efficiency program got started, and what are the main components of the program?

I initially developed the energy efficiency program with the help of a grant from the U.S. Department of Energy (DOE). Some of my contacts at the Environmental Protection Agency (EPA) already knew I was interested in energy efficiency so they gave me a heads up about the DOE grant opportunity. Since the grant application required a 20% non-federal dollar match, we jumped at the opportunity to create a partnership with NHSaves, an energy efficiency consortium of New Hampshire’s four largest electric utilities, for that match. DES was awarded the DOE grant, so we had $360,000 to get our energy program started in 2016. The partnership also helped bring awareness of NHSaves incentives since wastewater operators had not typically participated in the rebate program. Since completing the requirements of the DOE grant, we have continued to operate the energy efficiency program through the Clean Water State Revolving Fund (CWSRF) and more recently the American Rescue Plan Act. The main components of the program revolve around education, energy audits, and benchmarking.

How did you get utilities interested in participating in the program?

To garner interest in the program, we focused on working with wastewater systems whose owners and operators were already interested in exploring energy efficiency. It may be like this in other states as well, but in a small state like New Hampshire, it’s all about relationships. I personally know many of the wastewater operators in the state so I could call and tell them about the program, explain the potential benefits, tell them what to expect and judge their level of interest. If they aren’t interested, then they won’t likely implement the findings of the energy audit, and time and money is wasted on both sides.

For communities who have been proactive and implemented the findings of the initial energy audits, we are doing case studies as appropriate, or at times, we will conduct a new audit so they can have a new list of projects to work on. When it makes sense in terms of cost effectiveness, these follow-up audits may also include renewable energy measures. By providing a second audit, we are promoting the “Plan-Do-Check-Act” cycle of continuous improvement, and we continue to develop and support our energy efficiency champions.

Many of these operators are dealing with aging equipment, and so we work with them during the energy audit to try to build energy efficiency principles into equipment replacements/upgrades they will be making anyway. Since we focus on asset management in our state, the energy efficiency piece falls right in line with asset management. If we can get wastewater system owners and operators to pay attention to their energy use, they can use the energy data to help build a business case, along with operation and maintenance data, and vulnerability data to help justify the replacement and/or refurbishment of equipment. We are pushing for data-driven decision making to make a more impactful capital improvement plan and to improve communication between operators, system owners and system rate payers.

Based on the energy audits, what is the break-down of energy use at WWTPs?

Typically, aeration and pumping are the two biggest energy users for wastewater systems. Aeration has ranged from 15% to over 70% of the energy use at various plants around the state, although this can vary widely from system to system. An example I like to provide is energy use of three very similar, small lagoon systems in which the energy efficiency recommendations were very different for each plant. One was all about aeration, one was all about pumping and one was all about electric heat and insulation. Because of these different focuses, you can’t assume that the energy savings will be the same at each plant.

What are some common solutions or projects from the audits that small wastewater systems can consider for decreasing their energy use?

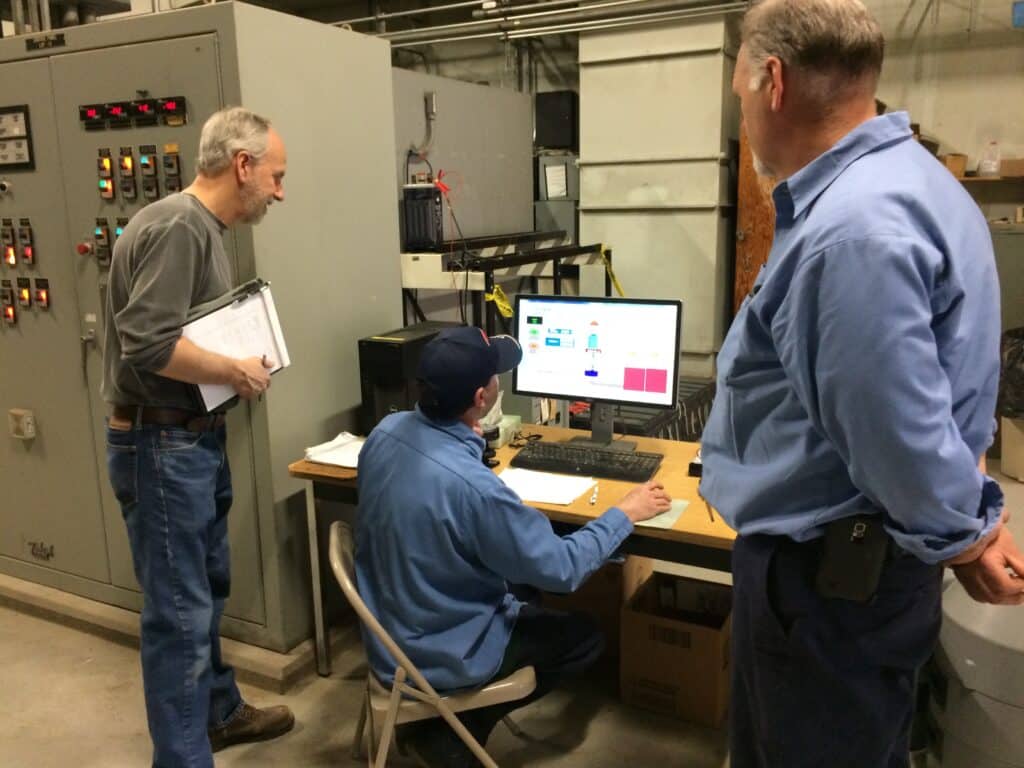

Variable-frequency drives (VFD) are commonly cited, either the installation of VFDs or the programming of existing VFDs. Frequently, we find that VFDs have been installed but were never programmed so the equipment is running at full speed. The operators don’t get the training they need to manually adjust or program the VFDs, so this a perfect opportunity to reduce energy consumption. Optimizing aeration, through dissolved oxygen monitoring and controls, is a common measure. Turning down the heat in areas that are only periodically occupied is another common measure. Sometimes the measures are very basic but very helpful in saving energy.

For wastewater, the energy audits are identifying about 28-30% potential energy savings with a 3-year or less payback before incentives. Since 2016, DES has completed about 50 wastewater system energy audits where we include both the treatment plant as well as pump stations.

How does DES assist small systems in funding these energy efficiency projects?

We keep preaching that without implementation, the energy audit is just another report. So we are supporting implementation with significant financial incentives. Any of the projects identified in wastewater energy audits are eligible for either grants or principal forgiveness through the CWSRF program. These incentive programs can cover up to half the implementation costs. Then, when combined with incentives from NHSaves, up to 85% of the implementation costs are covered.

Without financial support for these energy efficiency projects, many of the projects would not move forward even though they make cost-effective sense. When we can help communities use data to prioritize their system improvement needs while also providing incentives to move projects forward, we all benefit. To make sure communities take advantage of all the available funding, we require them to reach out to NHSaves when we commit our funding. ARPA funding has allowed DES to offer 100% grants up to $250,000 for energy audit measure implementation.

What have been some of the accomplishments of the program?

One accomplishment has been getting operators to think outside the box and look at alternatives. Since these plants were originally built, the primary focus for operators has been meeting permit limits. Through the energy efficiency program, we are working with them to help them meet permit limits more efficiently. The operators are also finding that as they gain better control over their systems with energy saving automated controls, their effluent quality is improving. We are also seeing operators get more comfortable with trying different things at their plants. They may find that the measure as recommended didn’t work but an alternative they came up with did work.

Another accomplishment is through the design process. We have been working to get design engineers to include energy efficiency in the design of upgrades because efficiency included in the initial construction of a facility is much more effective than retrofitting efficiency. To help this, DES included right-sizing requirements in our design standards back in 2014. We also developed energy efficiency design guidance documents that link with the existing design standards to help design engineers consider energy efficient alternatives for upgrades.

Another accomplishment of the program is the continued interest of the operators and the community. By working with operators who are interested and engaged, we have developed champions who help grow the program. We encourage those operators to share their successes with their peers through presentations as well as through case studies. Sometimes, significant energy savings are available at little to no cost.

Some utilities may see these improvements as a part of the bottom line in reducing costs, but would you agree that there is a bigger picture here in being more sustainable with climate adaptation?

Using less energy certainly is a huge factor to mitigating climate change. As we move toward electrifying everything to reduce our dependence on fossil fuels and move toward decarbonization, our electric grid does not have the capacity needed for all the added demand. We have recently expanded our energy program to include renewable energy when site conditions allow. All of our energy efforts today go toward climate change mitigation or slowing down climate change.

The program is also working on helping wastewater utilities adapt to climate change to improve their resiliency. We recently hired a Resiliency and Adaptation Manager and a consultant to conduct climate change vulnerability assessments at nine systems around the state. This contract will help us develop a program to roll out to the rest of the state. Overall, we will see many more opportunities when we stop looking at “wastewater” as a waste and start treating it as the resource that it really is. Water and biosolids will both be critical resources in our future and will be important components in addressing climate change.