In a small town nestled in the rolling hills of Iowa, the local wastewater treatment plant (WWTP) serves as critical infrastructure in the small community of 4,000 people, ensuring clean water and supporting public health. For the last few years, its operators have been struggling with a growing problem of increasing energy costs and peak demand charges. The plant’s monthly utility bills have been slowly eating into the facility’s tight budget, which can impact operations and maintenance of the facility to perform adequately. Between hefty electricity bills and demand charges, keeping operational expenses under control can feel like a constant uphill battle for the facility.

The plant’s manager, who has been with the WWTP for over a decade, is no stranger to challenges with aging equipment, unpredictable inflows, and the occasional harsh winter, but the latest increase in utility bills was a wake-up call. Currently, demand charges account for nearly 1/3 of the plant’s total energy cost, all because of a few hours of high energy when the plant’s pumps and aerators run at full capacity. With these expenses straining the budget, it became clear that improving energy efficiency is not only a way to enhance environmental compliance and operational reliability, but it was also quickly becoming an economic necessity.

The Challenge: Energy Costs and Demand Charges

Wastewater treatment is an energy-intensive process. From pumping and aeration to disinfection and sludge processing, these essential operations require a steady and often substantial supply of electricity. This constant draw translates into significant monthly energy bills and additional demand charges. These charges, levied by electric utilities based on the highest peak power demand within a billing cycle (highest 15–30-minute period of high energy use), can constitute a significant portion of the total energy expense for WWTPs. For WWTPs serving rural or small communities with limited budgets, these unpredictable spikes can create serious financial strain, not just on the WWTP but on the residents and ratepayers, making energy and cost management critical.

To address these growing challenges, the small Iowa-based WWTP facility conducted a basic energy assessment using 15-minute interval energy use data provided by the electric company and looking critically at plant operations. They found that the WWTP’s aeration system and pumps were the biggest energy consumers. This high consumption can also be associated with the plant’s outdated control systems, which ran equipment at full power regardless of actual treatment needs. The data obtained from the utility showed that electricity use peaked during morning and midday hours, aligning with the plant’s highest demand periods and thus triggering significant demand charges.

A Suite of Solutions: Energy-Saving Strategies for WWTPs

Effective energy management is crucial for wastewater treatment plants and their surrounding communities. After identifying their issues, the Iowa WWTP is considering implementing strategies like solar power with battery storage and smart digital technologies which can significantly reduce energy costs and enhance plant efficiency. These improvements will not only lower expenses for the WWTP but can also help in improving water quality and efficiency of the plant.

The Bright Solution: Solar + Battery Storage

Solar photovoltaic (PV) systems paired with battery storage offer small WWTPs a reliable and cost-effective way to reduce energy costs and dependence on the grid. Solar panels generate clean electricity during daylight hours, while batteries store excess energy for use during peak demand periods or at night, when electricity rates are often higher. Solar with batteries allows WWTPs to:

- Reduce energy costs: Offset grid electricity with solar power and use stored energy to avoid high-cost peak periods.

- Mitigate demand charges: Smooth out energy usage spikes by discharging batteries during peak demand, effectively shaving off those costly demand peaks and lowering demand charges.

- Enhance resilience: Ensure critical operations continue during power outages, a growing concern with increasing extreme weather events.

Smart Optimization Solution: Demand-Side Strategies

While solar with battery storage provides a powerful foundation for energy savings, demand-side energy management focuses on optimizing how and when energy is used. By reducing peak demand, shifting loads to off-peak periods, and anticipating demand with treatment flows, small WWTPs can achieve significant cost savings. Key strategies include:

- Peak Demand Reduction: Identifying and modifying operational schedules of energy-intensive equipment like pumps or blowers to avoid simultaneous operation during peak demand periods. This might involve staggering start times or optimizing process cycles. For example, deferring non-critical processes, such as sludge processing, to off-peak hours to flatten the demand curve.

- Upgrade Equipment: At the end of their useful life, replace outdated, energy-intensive pumps and aerators with high-efficiency models. Ensure that variable frequency drives (VFDs) are installed on motors and programmed for optimal use in conjunction with sensors to adjust power usage based on real-time needs. Integrating life cycle costing approaches while replacing the equipment at the end of its life would be essential.

- Install Sensors and SCADA Systems: Supervisory Control and Data Acquisition (SCADA) systems, combined with sensors, are the backbone of modern demand-side management. These systems collect data, monitoring flow rates, dissolved oxygen levels, and in some cases equipment performance, enabling operators to improve plant operations and optimize energy use. For example, the aeration system, which consumes 30-60% of the plant’s energy, could adjust blower speeds based on actual oxygen demand rather than running flat-out. It allows operators to make informed decisions about when to run equipment, potentially shifting non-critical loads to off-peak hours. The SCADA system can also be programmed to work in harmony with the solar and battery setup, charging the batteries when solar production is high and discharging them during peak demand windows.

- Monitoring Incoming Flows: Real-time monitoring of incoming wastewater flows can optimize energy use by aligning treatment processes with actual demand. The EPA highlights case studies where utilities deployed sensor networks with flow meters and rain gauges to collect real-time data, analyzed by real-time decision support systems (RTDSS). This enabled predictive adjustments to manage inflow/infiltration, reducing costs significantly. Similarly, another system in the Midwest implemented an RTDSS with sensor networks to monitor flows, allowing operators to anticipate treatment plant capacity up to an hour in advance and adjust pumping rates, enhancing efficiency and resilience.

Along with strategic energy management, the technologies discussed above also establish a robust foundation for regulatory and permit compliance, delivering high-quality effluent treatment at minimal cost. They reduce facility maintenance needs while continuously collecting reliable data to ensure ongoing adherence to regulatory standards.

Getting Started: Implementation and Funding

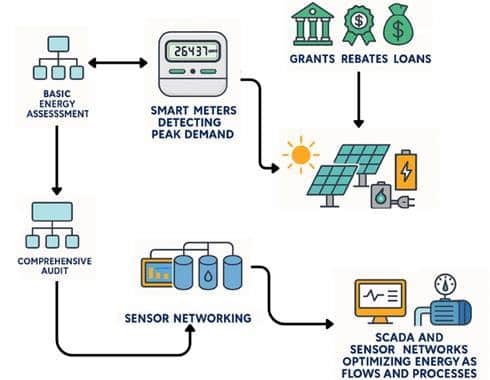

To advance energy efficiency and resilience, the Iowa WWTP operator could begin with basic energy assessment which can be followed by comprehensive energy audit and/or use smart meters and sensors to identify peak demand and high-energy processes. The facility can also consider doing small investments as a pilot project in real-time sensor networks and SCADA systems, to optimize flows and equipment use. The facility could partner with local utilities and/or renewable energy providers to explore Power Purchase Agreements (PPAs) or Energy-as-a-Service models, enabling solar, battery storage, and high-efficiency equipment installations without upfront costs. They should also try to leverage grants, rebates, or low-interest loans from the state, federal or utility programs to fund upgrades.

Conclusion

The rural Iowa WWTP and others in similar situations can overcome the challenges of rising energy costs and demand charges by transforming operations through strategic energy management and embracing innovative solutions. By integrating solar power with battery storage and implementing demand-side energy management strategies, these facilities can significantly reduce utility bills, mitigate costly demand charges, enhance resilience and operational efficiency. While upfront costs may seem high, financing options like Power Purchase Agreements (PPAs), grants, and utility incentives make these solutions accessible. The long-term savings and operational benefits far outweigh the initial investment, offering a compelling return on investment. The future of small WWTPs lies in these sustainable, cost-effective technologies.