The benefits of preventive maintenance are well established. Now you must decide what to do and when to do it. Luckily, there is a tool to help you answer those questions. The electronic preventative maintenance logs provided by the EPA gives you a step by step outline and schedule to help utility operators stay on top of maintenance within their system.

Although it has been proven that customers are willing to pay for increased service when they desire it, decision-makers, who operate under the common belief that customers want water to be cheap, look for places where budgets can be cut. Oftentimes, the first line item to be cut is maintenance: a decision which focuses only on immediate cost reductions but ignores the long-term costs. In reality, cutting the maintenance budget is the more expensive option because you end up replacing equipment sooner and in an unplanned manner. Oftentimes this unplanned maintenance and replacement (otherwise called reactive maintenance) makes your job much harder and much costlier. So how does maintenance help?

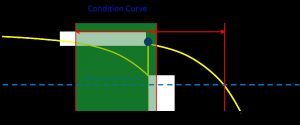

Water utilities provide a set service at a defined cost and effective maintenance will extend the life of the many assets used at a water utility, therefore saving costs in the long-run. An asset’s condition declines with use over time until it reaches a point where it is no longer capable of providing the level of service needed and ultimately reaches failure. If intervention is completed before reaching that point, by completing maintenance on the asset, the asset’s condition is improved, extending the life of that asset.

Assets throughout the system are different and while some assets should be allowed to run to failure without intervention, others should have routine maintenance done, and others still should have routine and preventive maintenance completed. Finally, the highest dollar assets likely should have predictive maintenance completed. Research has shown that doing preventive maintenance saves money versus operating in reactive mode,1 while selectively adding predictive maintenance has been shown to save even more.2

The benefits of preventive maintenance are well established. Now you must decide what to do and when to do it. Luckily, there is a tool to help you answer those questions. The Environmental Protection Agency (EPA) has released an electronic preventive maintenance tool. It is an interactive PDF file designed to be used electronically or in printed format. The tool is called the “Preventive Maintenance for Small Public Water Systems Using Groundwater” and it was designed with the following system characteristics in mind:

– Designed to help small systems:

- Plan and record O&M activities

- Create a permanent print or digital record of those activities

– Intended for ground water systems with up to:

- 6 wells & well pumps

- 4 storage tanks and/or pressure tanks

- 4 chemical feed pumps

- 4 booster pumps

– Could be used by surface water systems as part of O&M program.

Learn more about the electronic preventative maintenance logs or download the files here. The SW EFC recently hosted a webinar that walks you through downloading and using the tool. The webinar can be viewed here.

Sources:

1 “According to a case study by the Office of Energy Efficiency and Renewable Energy, practicing Periodic component replacement in the form of preventive maintenance saves an estimated 12 to 18 percent over reactive maintenance.” Making the Transition to Proactive Maintenance, Jeremy Write www.machinerylubrication.com

2 “Condition monitoring can decrease your motor operations and maintenance (O&M) expenses by up to 25 percent”How does condition monitoring prevent motor failures? Nicole Dyess, Uptime https://reliabilityweb.com/articles/entry/how-does-condition-monitoring-prevent-motor-failures