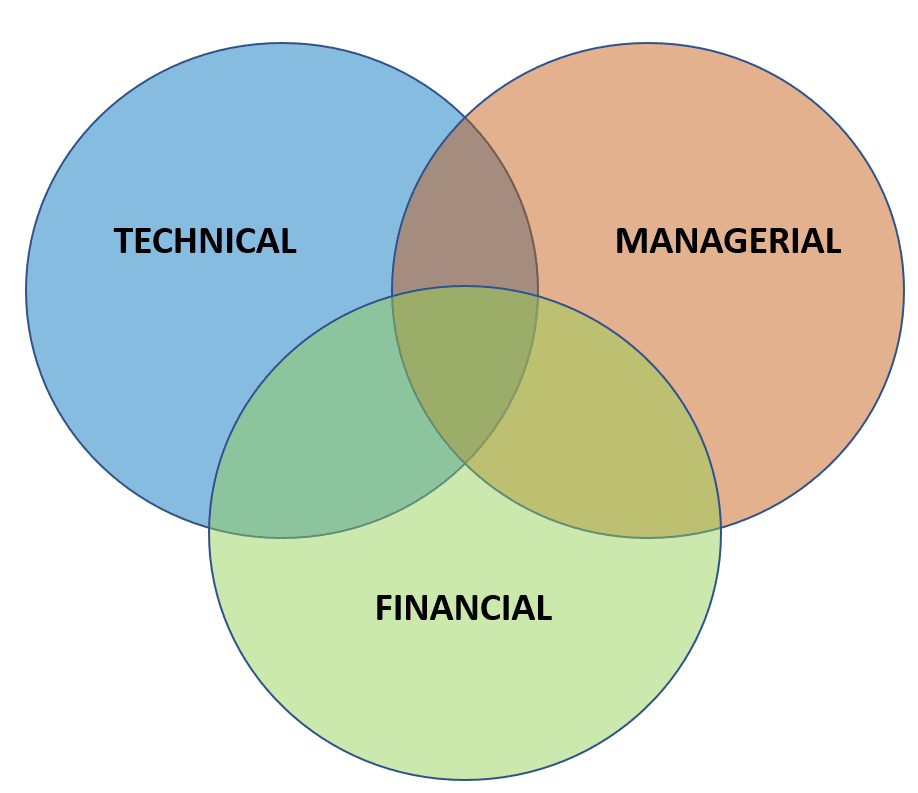

Did you know there are three strategies that can help any wastewater utility improve its capacity? The US Environmental Protection Agency (USEPA) expresses the capacity of a utility in terms of technical, managerial, and financial—or TMF—capacities that work together to build overall capacity and provide a way to analyze strengths and weaknesses. Let’s look at some strategies that wastewater utilities can use to improve their TMF capacities.

How to Build Technical Capacity (T)

Technical capacity encompasses the condition and performance of a utility’s equipment and infrastructure and the knowledge and skills of its operators. Knowledge management, an important aspect of technical capacity, includes gathering and using condition assessment data about assets and capturing operators’ experiential knowledge about operating, maintaining, and repairing utility equipment.

Technical capacity can be increased through an asset management program that includes replacing and optimizing assets when needed as well as operator training. A first step toward establishing an asset management program is to implement a condition assessment program for all assets and equipment. For example, underground sewer piping can be inspected using closed-circuit television (CCTV) cameras and rated using a uniform condition assessment process like the Pipeline Assessment Certification Program (PACP). And, equipment such as tanks, pumps, grinders, mixers, and aerators can be periodically inspected and rated by trained operators or professional inspectors. A very simple approach can be used to start. The simplest method involves using staff knowledge and assigning condition rankings based on that knowledge. The resulting condition assessment data helps a utility to prioritize resources for maintenance and repair and to prevent outages, overflows, and breaks that pose potential compliance problems.

In time, an asset management program will produce a measurable cost benefit; however, it can be expensive to launch. To keep costs down, a utility can begin by inspecting a percentage of its sewer pipe each year instead of its entire system at once. Also, it is advisable to begin with the most critical assets first. For example, a force main section of the sewer near a sensitive waterway or under a major highway would be a higher priority for inspection. If the utility has tracked sewer line failures, a map showing these locations can guide the system in prioritizing what to inspect first. As a utility collects condition data for its assets, the utility should record and store the data in a simple spreadsheet program or more complex geographic information system (GIS) that connects asset data and location in order to allow the data to be searched, analyzed, and used for asset management.

How to Build Management Capacity (M)

Managerial capacity includes decision-making skills, strategy, policies, and staffing tasks. Key aspects of managerial capacity are efficient use of resources to accomplish the utility’s mission and sustainability, or managing the utility in a way that it meets the community’s needs into the foreseeable future.

Effective utility management (EUM) is a no-cost tool that wastewater utilities can use to assess their performance according to ten attributes of effectively-managed utilities (learn more and find case studies at watereum.org). This assessment process helps identify aspects of the utility that are paramount yet in need of improvement. Once aspects are identified, a utility can prioritize and measure improvement efforts.

As an example, a utility may determine that infrastructure stability is very important, however its sewer network contains aging and deteriorating pipes. The utility can improve infrastructure stability by launching a condition assessment program and making needed repairs and replacements for prioritized pipes. For its condition assessment program, the utility may use EUM measurements and benchmarks, such as the maximum number of sanitary sewer overflows (SSOs) per 100 miles of sewer main.

How to Build Financial Capacity (F)

Financial capacity includes budgeting and rate-setting tasks that ensure a utility can cover operation and maintenance activities, respond to emergency repairs, and set aside sufficient funds for future asset replacements.

Financial capacity can be improved by having an adequate user rate that covers operation, maintenance, replacement, and debt service. An effective measure of a utility’s revenue sufficiency is the operating ratio (OR), which is calculated by dividing annual revenue by annual expenses:

OR = Revenue ÷ Expense.

Sufficient financial capacity is indicated by an OR greater than 1.0. An OR equal to 1.0 means the utility has the exact revenue to cover its expenses but none left over for reserve funds for asset replacements or responding to emergencies. Therefore, a target OR should be greater than 1.0. For example, a utility with an annual expense of $100,000 and a target OR of 1.4 would establish a user rate to bring in a total revenue of $140,000, of which $100,000 covers operation and maintenance expenses and $40,000 funds asset reserve accounts, loan payments, and emergency response, and offsets depreciation.

The debt service coverage ratio (DSCR) helps to measure a utility’s financial capacity for loan payments associated with utility infrastructure project expenses. Lenders may require that utilities have a minimum debt ratio, such as 1.2 required for USDA Rural Development Loans. To calculate debt ratio, the net revenue—found by subtracting total expense from total revenue—is divided by the annual debt payment including principal and interest:

DSCR = [Annual Revenue – Expense] ÷ Annual Loan Payment

For example, a utility with a revenue of $140,000, a total expense of $125,000 and an annual loan payment of $10,000 would have a DSCR of 1.5:

[$140,000 – $125,000] ÷$10,000 = 1.5

Conclusion

Three strategies can help any wastewater utility improve its TMF capacities: An asset management program captures asset knowledge through condition assessment and helps with prioritizing the use of resources while minimizing outages and compliance problems. Effective utility management helps to identify attributes needing performance improvement in order to create strategies for prioritized and measurable improvement. And, financial ratios can provide a measure of the adequacy of rate structures and the sufficiency of revenues to cover operational costs, asset replacements, and loan payments. Most importantly, building TMF capacity helps utilities to become sustainable, providing sufficient service to their customers into the foreseeable future.

For additional resources and no-cost workshops, please visit efcnetwork.org. No-cost technical assistance is also available for wastewater systems producing less than 1.0 MGD or water systems serving a population of 10,000 or less.